Chirp ran fine on Linux when I needed it to program a UV-5R a year or two back - was provided in a flatpak then but looks like they use a Python wheel file now.

Chirp ran fine on Linux when I needed it to program a UV-5R a year or two back - was provided in a flatpak then but looks like they use a Python wheel file now.

Self checkouts that just let you scan items without issue and accept payment are a nice enough idea for a bag or less of shopping, my problem with them is how they are implemented in reality (in Australia anyway). The first implementations I encountered I considered an useful addition but both the machines and the staffing changes due to them have steadily gone downhill in terms of user experience.

Instead of a quick painless experience you get a horribly touchy weight sensor which can’t reliably handle particularly small items, particularly large items, or non-standard bags (and there are no longer standard bags due to plastic bag bans), a machine which demands assistant intervention at the slightest issue (and the assistants are understaffed so never arrive quickly), and when you finally get to payment it makes you click through an annoyingly slow interface to tell it you don’t have a rewards card and don’t care to donate to some charity before it will activate the card reader. To make things worse the manned checkouts are never staffed at a level - if any are even open - to cater for people with full trolleys so these end up clogging up the self checkouts (which have tiny bagging areas and are not intended to handle a trolley load) and making everything slower.

The icing on the cake is the self checkout treating you like a thief and throwing errors if the camera system thinks you didn’t scan something in the trolley or letting off an alarm like you’re trying to make off with something when you just want to buy a can of paint.

As in plasterboard sheets? I don’t see why not if hand loading, plenty of vans will fit a 2400x1200 sheet (my Transporter fitted a bunch of plywood with room to spare). Loading one with a forklift is harder due to no side access long enough to fit 2400mm but that’s a problem shared with tub back utes. If however your plasterboard pallet is side accessible a van with barn doors (like you’d buy if pallets were a priority) will allow you load it in fine.

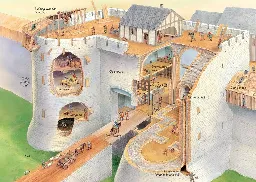

I find it a bit amusing that the sepia toning effectively colourised the image.

The design of the front forks also assists with stability - having some rake and trail means the front wheel has a tendency to self centre (particularly at speed).

Without modern metallurgy and and the associated industrial manufacturing base it’s a lot harder to build a single mill to effectively use all the potential energy. A multiple mill setup like this allows you to extract most of the energy without reaching the limits of how much force you can put through machinery made of wood (the shafts and bearings are likely also wood, not just the wheel buckets), stone, and low strength metals.

Learning on a transmission with >6 speeds is hard mode, they do take a little more thinking with the gear pattern than in a car. Synchro versions are not that hard if you’re used to a regular manual but adding another thing to learn is not ideal when starting out. If it was a non-synchro variant then good luck getting someone to pick that up without a few solid hours of learning time.

If you were being taught by someone used to heavy trucks it makes sense why they didn’t tell you to push the pedal right in - on many (all?) non synchro transmissions pushing the clutch all the way in brakes the input shaft and if you’re moving you then have to resynchronise it with the gear speed in order to get into gear.

Note you don’t actually have to push the clutch in all the way in a car either, all that really matters is getting it past the point where the clutch is fully disengaged. After all the clutch plate is either touching the flywheel to some degree or it’s not touching, once it stops making contact pushing it further away doesn’t make a difference. When first starting out though it’s easier to just push the pedal all the way in - save thinking about finer details until you’re comfortable with the basics.

If I’m doing a small shop I’ll take a bag in, fill it up as I go, then everything goes out at the checkout and ends up back in the bag. I’ve never had anyone care about this and I’ve been doing it for a few years now (ever since the old plastic bags got banned in my area).

The ACT does get a bit cold in winter, but I feel like it’s closer to England than Finland (if England was drier and actually got hot in summer anyway). We are after all talking minimums of -5 or -6 for the coldest days in winter and snow normally only settling on the tops of the nearby mountain range (and temporarily at that).

I think the main problem with searching for fediverse posts is not that they’re not indexed but the lack of a singular tag to append when you want to search for them. To search for reddit posts it was easy because you could put in your keywords and stick ‘reddit’ or ‘site:reddit.com’ onto the end, but now there’s too many domains to keep track of and you can’t rely on appending ‘lemmy’ pointing a search engine towards all Lemmy instances, let alone kbin/mbin instances.

It appears to be a 1970s bike (I would take a stab at a Yamaha LT3) and by that period shutter speeds of 1/500 or 1/1000 were readily available amongst better quality cameras. That would be plenty to get a clear shot of the spokes on what would be a relatively slow moving bike (I would assume <40km/h, likely noticeably less). I’ve got several 50s era cameras that have 1/500 top speeds, so even if the bike was new at the time of the photo it didn’t require a new camera to take the shot.

I would not say having the inside foot off the peg and held forward in this situation is an indicator of the photo being fake, seeing as it’s a common behaviour when riding dirt bikes.

I think a mud track with occasional bits of gravel is basically what the display is suggesting, it’s just that the mud is dry.

You pour a bit of boiling water down the side of the cylinder then run your hand down where you poured the water - you will feel a clear delineation in the temperature of the cylinder at the level of the liquid gas inside.

Boiling the jug and pouring a bit of hot water on the cylinder seems like it’d be less work than digging out the Wii fit gear, unless of course they use it more regularly rather than just for weighing gas bottles.

Indeed, I just realised that point - the force of propelling the anchor is tiny compared to what you can exert on the ship once the anchor is hooked.

A trebuchet primarily transforms downward motion (of the counterweight) into forward motion, so it would actually work - the trebuchet doesn’t push the ship back as much as it pushes its load forward. This is particularly so if your trebuchet has wheels and you have room on your ship to accommodate it rocking back and forth when firing.

Edit: Thinking about it this technique would work even with something that does impart equal backwards force on the ship when firing a projectile, because there is considerably more force involved in winching the ship towards the anchor than what is involved in actually moving the anchor. You aren’t pulling against the inertia of a free floating anchor after all, you’re pulling against the ground the anchor has hooked into.

Yes, the move towards integrating the infotainment further into the car with propitiatory parts instead of generic sizes and not separating out vehicle related controls is definitely going to make long term upkeep harder.

All cars could last a lot longer if people kept maintaining them and - importantly - didn’t damage them. Electric cars are not going to be immune to this, I can’t see them lasting much longer on average than ICE cars.

Keep in mind that even when you change out the engine for something with less parts the rest of the car still remains and contains things which will eventually cause issues. For example I bought a cheap van a few months ago and here’s some of the reasons it was cheap that are not ICE specific:

Presumably the previous owner just didn’t want to spend the money on fixing these issues as they arose, and eventually it added up into a lot of potential expense (if you have to pay someone to fix it for you) and more reasons to sell the car. Such behaviour seems pretty common in my experience and I fully expect it to continue with EVs. It’ll be hard enough to get people to even maintain their brakes and change the motor coolant considering the natural reluctance of people to spend money on maintenance and this unfortunately prevalent idea that EVs don’t need it.

Funnily enough the main ICE specific problem with that van was just as much an electrical issue as part of the petrol engine - an intermittent secondary air injection error code which ended up being down to a combination of a sticking valve and a fuse with a hairline crack causing an intermittent connection.

Looks like I could buy one for $55k (AU) - would be kind of fun to have actually and cheaper than a lot of new 4wds. Pity some wowsers had issues with it running around with a machine gun, I feel like that’d reduce traffic problems…