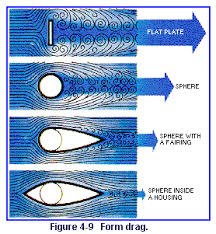

This is a good question and I don’t really know how this device would affect drafting and related manoeuvres. But if I had to guess, drafting behind a lead cyclist should still be beneficial, but the “zones” where it works might change.

So for example, the optimal distance lee-ward of a lead cyclist might become shorter or longer. Longer could mean more space to vie for that position directly behind the lead. But shorter might mean it’s impossible to draft without crashing into the lead.

Side-to-side drafting distances might also be affected, like how birds travel in a vee-shape. Maybe the vee would become wider? That might not be beneficial, though, if it’s so wide that it’s impossible to stay on the racecourse.

TL;DR: I have no idea, and aerodynamics are hard. That’s why I’m intrigued by the field.

This reminds me of the time I happened to be at a warehouse where an industrial motor control panel was being decommissioned. In the center of the panel is a large breaker, which was dutifully opened (ie powered off) before work commenced. But bizarrely, someone in the past managed to tap power from the supply-side of the breaker for some sort of monitoring sensor inside the panel. So when that circuit was cut through, there was a loud bang and the overhead lights went out.

No one was injured, although everyone was jumpy from the inadvertent light-and-sound spectacle. And a set of cutters gained a 12 AWG-sized (approx 4 mm^2) hole.

I may have misremembered some details, but my takeaway as a non-electrician was to 1) never assume a breaker handle at face value, and 2) don’t assume the prior person made sane choices.